- Home

- Catalogue

- Desktop Autoclaves

- 4002420

AUTESTER ST DRY PV lll

Autoclave for liquids and solids sterilization “Autester ST DRY PV lll” 25L

Capacity: 25 litres. Space for 12 bottles of 250 ml, 9 of 500 ml, 3 of 1000 ml and 2 of 2000 ml.

Conforms to the regulation - 2014/68/ue equipment under pressure.

Complete selection of programs. Displays in English - Spanish - French.

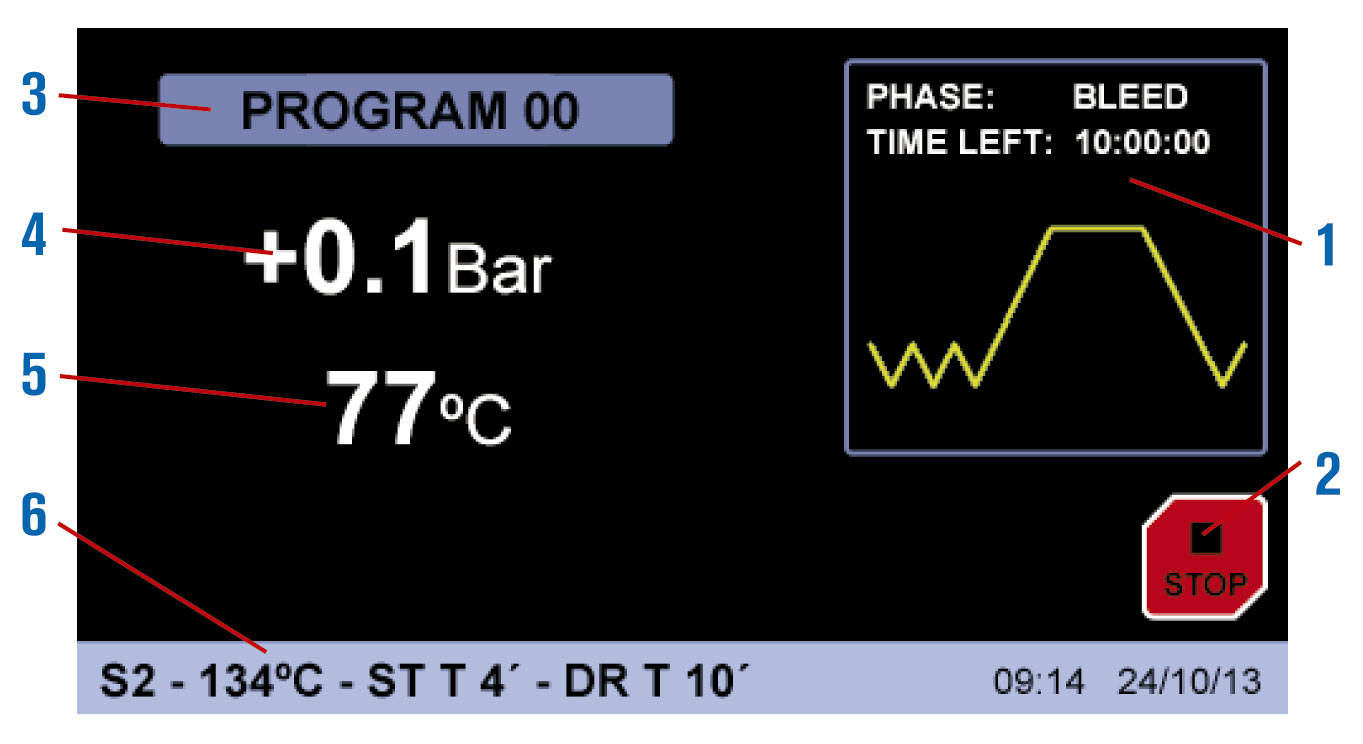

CONTROL PANEL

TFT touch screen with virtual pushbuttons.

1. Graphical representation of real time process

2. Start/Stop pushbutton.

3. Running program.

4. Press indicator.

5. Temperature indicator.

6. Running program parameters.

PRINCIPAL OF STEAM STERILIZATION

STERILIZATION IS THE PROCESS OF THE DESTRUCTION AND ELIMINATION OF ALL FORMS OF MICROBIAL LIFE, INCLUDING BACTERIA AND ITS SUBFORMS.

THE LABORATORY AUTOCLAVE CONSISTS OF A VESSEL IN WHICH STEAM FLOWS AT A HIGH PRESSURE WITH A STERILIZATION PURPOSE. SATURATED STEAM WILL IMMEDIATELY CONDENSE AND THUS RELEASING ITS HIGH EVAPORATION HEAT, WHICH IS IN FACT THE DESTRUCTIVE AGENT. IN ORDER THAT STERILIZATION WOULD BE EFFECTIVE, STEAM MUST BE SATURATED AND, CONSEQUENTLY, ALL THE AIR INSIDE THE VESSEL MUST BE PURGED BEFORE INITIALIZING THE PROCESS.

FEATURES

Sterilization chamber and lid made from AISI 304 stainless steel.

External case epoxy coated.

Digital control of all autoclave operations.

TFT 3,5’’ touch screen .

Air filter, purifies air before entering in the sterilization chamber.

Separate clean water reservoir and waste water.

RS-232 Interface output of parameters to a computer or for printer.

USB output for PEN-DRIVE data logging.

SAFETY

Safety valve.

Prevents the door being opened if under pressure or high temperature is produced.

Temperature safety thermostat.

Door closed correctly detector

Thermally protected lid.

MICROPROCESSOR FUNCTIONS

Controlled parameters are:

• Sterilization temperature from 105°C up to 134°C.

• Sterilization time from 3’ to 59’.

• Drying time from 20’ to 60’.

• Up to 10 user-configurable programs.

• Six operating modes:

- Solid 1 - Solid 2 fractions. - Solid 3 fractions - Drying - Liquids - Liquids 2 probes

• Verification test

- Vacuum - Bowie Dick.

• Settings:

- Units – languages (Spanish, English, French). - Printer module On/Off. - Clock:

date/time.

• Password for adjustment.

• Calibration.

- Temperature probe 1 - Temperature probe 2 - Water dosing - Presion.

• Audible and visual alarm for overtemperature and insufficient temperature.

• Network failures detection and memorization.

• Safety therrmostat by software.

• Sterilization cycles data logging with capacity for over 500 cycles.

• Internal cleaning program.

• Graphical representation of real time process.

MESSAGES

1. E 2PROM

2. RTC FAULT

3. SENSOR PRECISION

4. HEATER PROBE

5. CHAMBER PROBE

6. OVER PRESSURE

7. VACUUM

8. PRESSURE

9. BOILER TEMPERATURE

10. TEMPERATURE LOW FAULT

11. INPUT ERROR

12. STERILIZATION

13. LEVEL 1

14. LEVEL 2

15. DOOR

16. PRINTER NO PAPER

17 PAPER JAM

18. ELECTRICAL FAULT

| Código | Capacity litres | Ø (usable) | Depth (usable) cm | Height (exterior) cm | Width (exterior) cm | Depth (exterior) cm | Consumption w | Weight Kg |

|---|---|---|---|---|---|---|---|---|

| 4002420 | 25 | 30 | 35 | 58 | 46 | 59 | 2510 | 52 |

Accesories

Special tray

for bottles of 0.25, 0.5, 1 or 2 litres

Ink Printer “Microprinter”

(no thermal) Continuous paper roll with print out of temperature, time and mode. For use with pH and conductivity meters . Paper 2 1/4” (56 mm) wide roll. Interface RS232. Includes power transformer and interface cables. (5V-3A)