- Home

- Catalogue

- Desktop Autoclaves

- 4001735

Autoclave para esterilización “Autester ST DRY PV” 23 Clase B

Autoclave for sterilization “Autester ST DRY PV” 23 Class B

Capacity: 23 litres.

Temperature and cycle control by microprocessor.

Automatic fractional vacuum drying and purging system.

With programs at 121 °c and 134 °c (1 and 2 bar).

Horizontal desktop model.

According to directive: 2014/68/UE equipment under presure,3.3

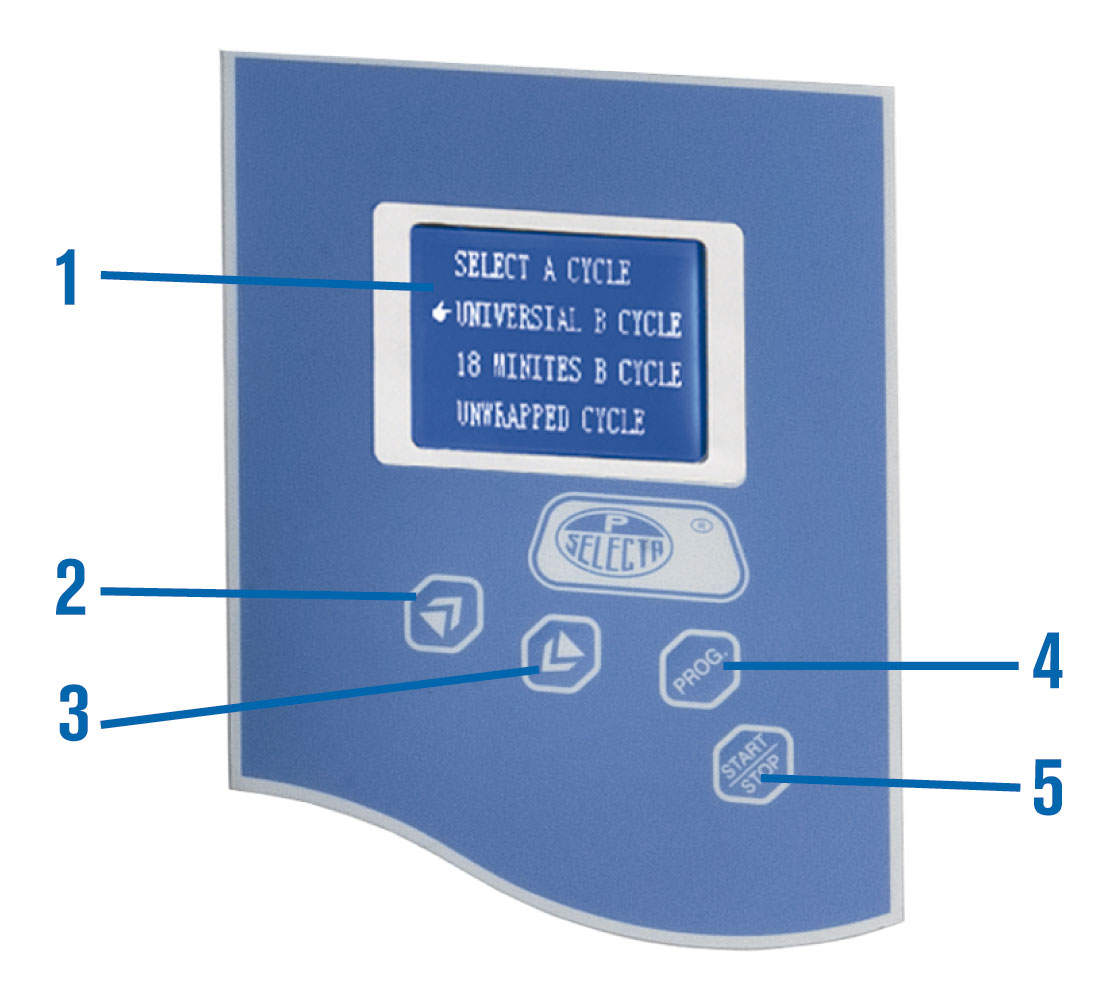

CONTROL PANEL

1. LCD screen.

2. Push button increase parameters.

3. Push button decrease parameters.

4. Push button menu.

5. Push button Start-Stop.

PRINCIPAL OF STEAM STERILIZATION

STERILIZATION IS THE PROCESS OF THE DESTRUCTION AND ELIMINATION OF ALL FORMS OF MICROBIAL LIFE, INCLUDING BACTERIA AND ITS SUBFORMS.

THE LABORATORY AUTOCLAVE CONSISTS OF A VESSEL IN WHICH STEAM FLOWS AT A HIGH PRESSURE WITH A STERILIZATION PURPOSE. SATURATED STEAM WILL IMMEDIATELY CONDENSE AND THUS RELEASING ITS HIGH EVAPORATION HEAT, WHICH IS IN FACT THE DESTRUCTIVE AGENT. IN ORDER THAT STERILIZATION WOULD BE EFFECTIVE, STEAM MUST BE SATURATED AND, CONSEQUENTLY, ALL THE AIR INSIDE THE VESSEL MUST BE PURGED BEFORE INITIALIZING THE PROCESS.

APPLICATIONS

"Class B" autoclaves are used within the field of general medicine, dentistry, veterinary, tattoo parlours and sterilization applications in general, to sterilize any material that could have been in contact with body fluids including blood.

The general capabilities of the instrument are regulated by EN 13060 that guarantees the differing sterilization applications.

The normal processes include: Solids with and without wrapping, porous material with and without wrapping and utensils that have cavities and holes (e.g. dentistry materials.)

To guarantee sterilization of these materials the “AUTESTER ST DRY PV” Class B, autoclaves, have an efficient staged vacuum, that performs a complete extraction of air that allows penetration of the steam vapour.

The same vacuum system is used to obtain the dry phase, which is required for perfect storage of sterilized materials.

The “AUTOCLAVES ST DRY PV” Class B includes verification and validation programs.

CONFORMITY

EN 13060 SMALL GENERAL PURPOSE STEAM STERILIZERS.

EN 61010-1 EQUIPMENT SAFE FOR LABORATORY USE.

EN 61010-2-040 SAFETY FOR STERILIZER EQUIPMENT FOR LABORATORY USE.

EN 61326 ELECTROMAGNETIC COMPATIBILITY FOR EQUIPMENT USED IN THE LABORATORY.

SAFETY

SAFETY VALVE: REVENTS THE PRESSURE EXCEEDING THE MAXIMUM SET LIMIT.

SAFETY THERMOSTAT: DISCONNECTS THE HEATER AGAINST OVER TEMPERATURE OR LOW WATER IN THE RESERVOIR.

THERMALLY INSULATED LID.

Diagram showing the function cycle autester st dry pv

Staged fractional vacuum: Extracts air from the load that permits absolute steam vapour penetration.

Sterilization stage: Sterilization within the time and temperature selected.

Dry cycle: Extracts the humidity from the load leaving it suitable for storage.

FEATURES

Digital electronic control.

Stainless steel internal chamber.

Staged vacuum purge.

Dry by vacuum

Incorporated steam generator.

Water reservoir to supply the chamber

High vapour penetration of porous material

Used in digestive studies, ophthalmology, operating theatres etc.

Automatic or manual filling of the water tank.

Printer interface.

USB connection for parameters memorization (software included).

Similar Products

Accesories

Ink Printer AUTOCLAVE W 18/23 L.

Accessory for Autoclave Autester St. Dry PV # 4001734 & 4001735.